The Single Drinking Straw Packing Machine possesses the following technical characteristics:

Capable of packing, filling, and individually packaging drinking straws one at a time.

Features automatic product counting and alarm functions.

Offers adjustable packaging length through calibration, accommodating paper and BOPP film (or paper/film with a logo).

Can pack 150-260mm length straws of the same diameter without requiring spare parts adjustment. Furthermore, it allows for packing various diameter straws by changing specific spare parts.

Utilizes a three-set servo motor system for driving, PLC control, and a touch screen for setting personalized data to package straws of different lengths.

Equipped with a high-speed color calibration system for precise positioning with patterns.

Implements a temperature module system to regulate the heating temperature effectively.

Includes a stainless steel work table for durability and cleanliness.

The Single Straw Automatic Position Packing Machine is an advanced drinking straw packing machine that combines efficiency with precision.

Single Straw Automatic Position Packing Machine

| Item | KD-31D |

| Speed | 400-500pcs/min |

| main cutting motor | SERVOMOTORES 0.8KW |

| Main wrap motor | SERVOMOTORES 0.4KW |

| Main pushing motor | SERVOMOTORES 0.4KW |

| Hopper power | 90w |

| Heating power | 2*200w (use BOPP) |

| Packing material | Papel, BOPP film |

| Width of material | Papel: 25-33 mm plastic film: 25-60 mm |

| Straw diamter | 4mm—12mm |

| Straw length | 150-260mm |

| weight | 450kgs |

| Machine size | 1250mm X 1800mm |

| Automatic counter | 1 piece |

| Conveyer belt | 1 piece |

| Touch screen | 1 piece |

| PLC | 1 piece |

| Temperature control module | 1 piece |

| Photocell system | 1 piece |

PP drinking straw machines warehouse

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Loading Drinking Straw Machine Warehouse into container

Our Main parts cooperator as following brand,but standard parts all made from China.

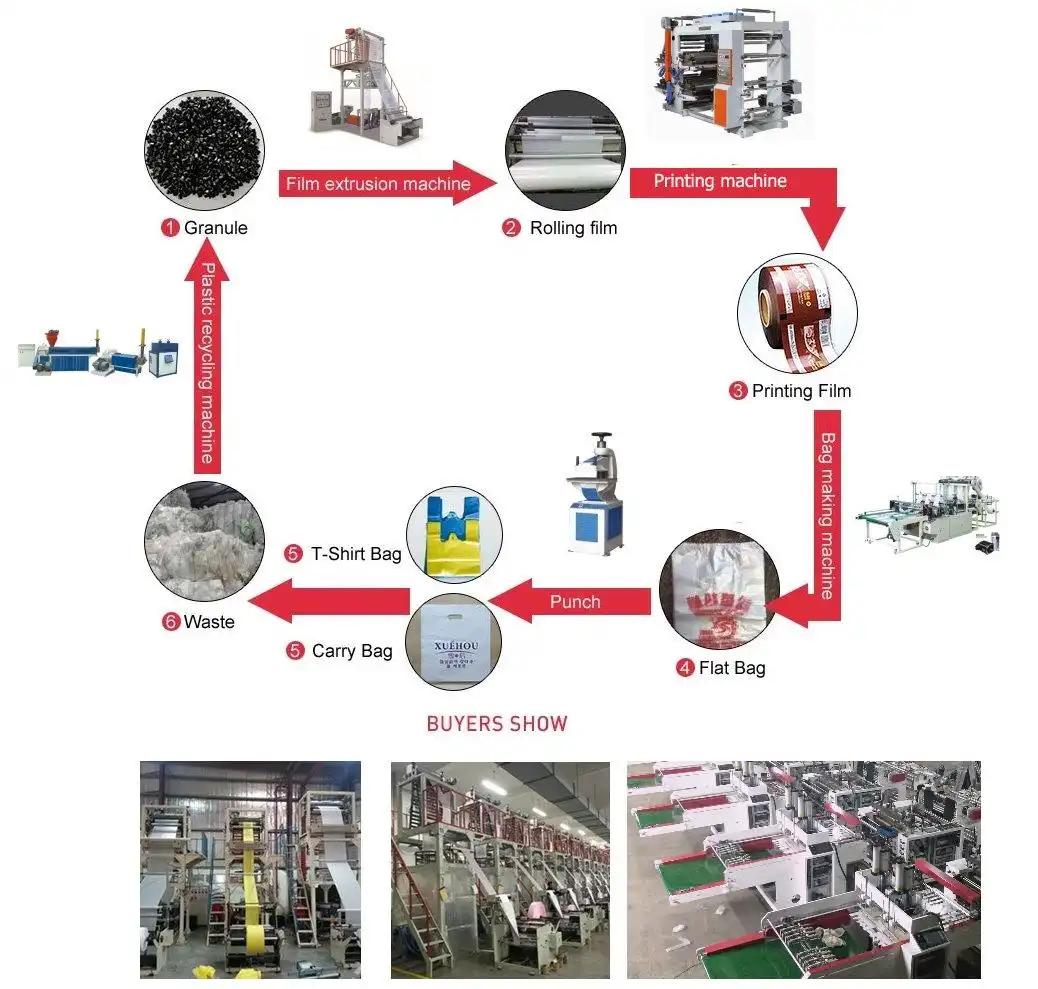

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;