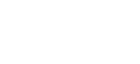

The Rotogravure Printing Machine features seven motors controlled by frequency vector conversion technology for main motor, unwinding, rewinding, and tension control. It ensures lengthways and transverse accuracy using a fully automatic registering device with pre-register function. Equipped with a video frequency system, non-shaft pneumatic conic node printing allows for easy printing plate changes. The machine includes a sealed hot wind circulation oven with automatic temperature control using diesel oil air-stove or electric heating. A pneumatic draw knife, swing frequency-adjustable single motor, and holistic moving oil frame with pneumatic pump circulation are also integrated. Additionally, a high-accuracy gear transmission box with patented technique is utilized for precise operation.

BOPP film

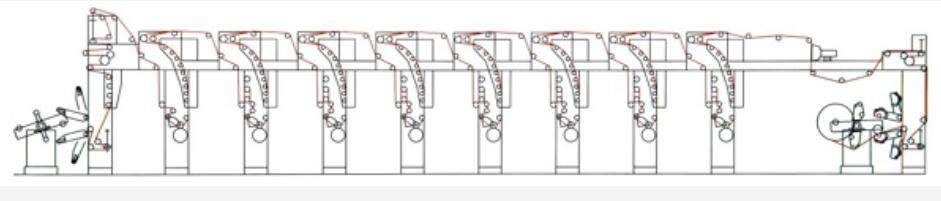

Application:

The machine is suitable for a cellophane,BOPP, PET, PVC,PE, aluminum foil, cigarette packet, China cypress paper, liquid carton and drum Paper (30-300 g/m2) has good printing performance of the drum Material of multi-color printing.

| Model of machine | KDASY-F800 | KDASY-F1000 | KDASY-F1200 |

| Width of Printing | 800mm | 1000mm | 1200mm |

| Max. Machinery speed | 180m/min | 180m/min | 180m/min |

| Max. Printing Speed | 150m/min | 150m/min | 150m/min |

| Max. Dia. Of Roll | 600-800mm | 600-800mm | 600-800mm |

| Dia. Of roll core | 76mm | 76mm | 76mm |

| Version Accuracy | +/-0.1mm | +/-0.1mm | +/-0.1mm |

| Dia. Range of Printing Cylinder | 120-360mm | 120-360mm | 120-360mm |

| Total Power | 180kw | 200kw | 260kw |

| Outline Dimension | 8800×1600×2000mm | 8800×1800×2000mm | 8800×1800×2000mm |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

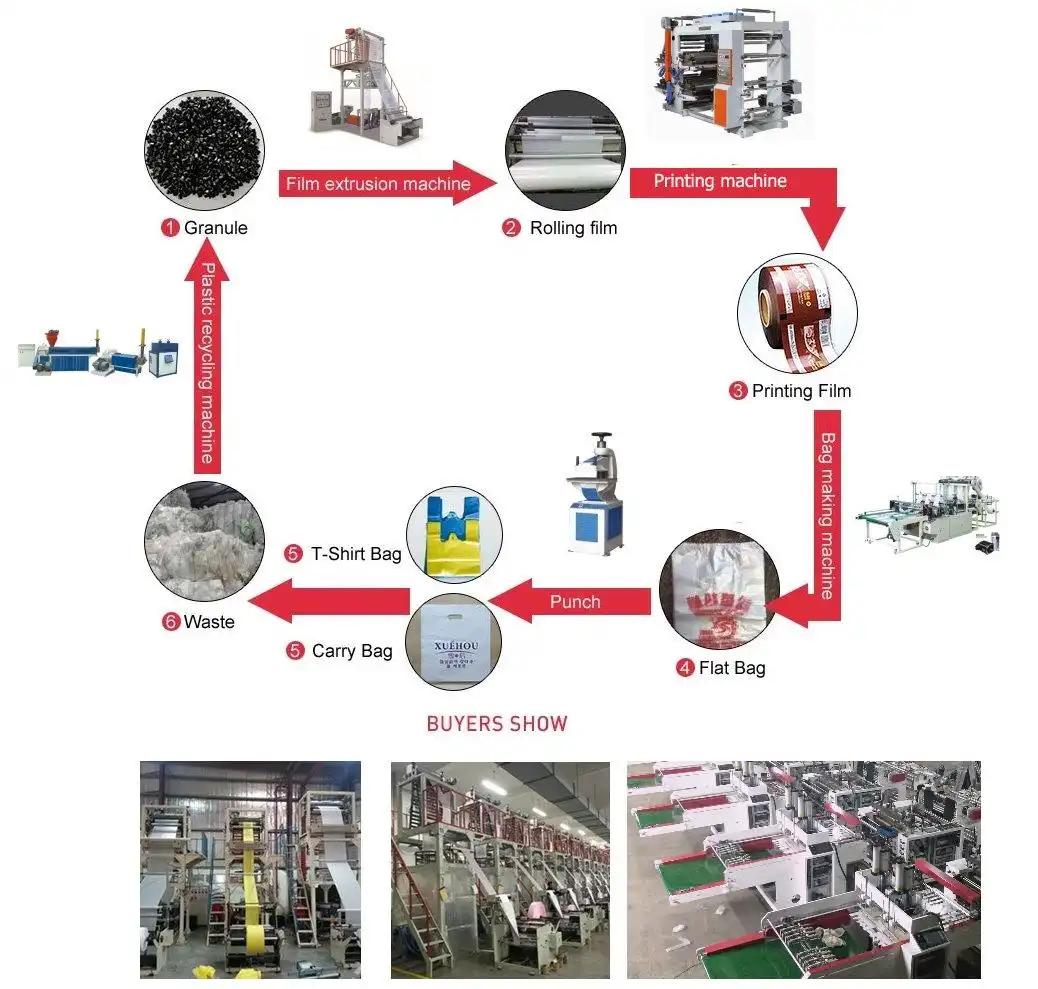

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;