High Speed Six Colors Flexo Printing Machine

The High Speed Six Colors Flexographic Printing Machine utilizes sensitization resin as the flexible printing plate and is designed for printing packaging materials like polyethylene, polypropylene bags, cellophane, and roll paper. This machine is an ideal choice for producing paper packaging bags for goods, supermarket handbags, vest bags, clothes bags, and more.

A Six Colors Flexographic Printing Machine is equipped with high-speed capabilities and a range of features. It offers easy operation, precise color registration, and flexibility in starting. The meter counter allows users to set the printing quantity as needed, automatically stopping the machine when the desired quantity is reached or when the material runs out. The machine’s pneumatic printing cylinder facilitates ink stirring and automatic lifting, while the anilox cylinder ensures even ink distribution. A reliable drying system, synchronized with high-speed rotation, includes an automatic circuit break feature when the machine stops. Additionally, a 360° continuous and adjustable longitudinal register device, along with frequency-controlled motor speed, accommodates various printing speeds. Convenient Jogging/Stopping buttons on the plate roller base and material rolling rack simplify machine operation during plate installation.

| YT-A6600 | YT-A6800 | YT-A61000 | YT-A61200 | |

| Max.material width | 600mm | 800mm | 1000mm | 1200mm |

| Max.printing width | 560mm | 760mm | 960mm | 1160mm |

| Heating power | 35kw | 35kw | 35kw | 35kw |

| Machine weight | 5000kgs | 5200kgs | 5400kgs | 5600kgs |

| Outline dimension | 6×1.8×3.5m | 6×2.0x3.5m | 6×2.2×3.5m | 6×2.4×3.5m |

| Printing colors | 6 colors (6+0,5+1,4+2,3+3) | |||

| Printing length | 300-1100mm | |||

| Machine speed | 150m/min | |||

| Printing speed | 100m/min (120m/min with optional:chamber doctor blade) | |||

| Material of Plate | Resin | |||

| Suitable Material | PAPER∶15~300g/m²、 NONWOVEN∶15-120G、PC∶10-120μm、OPP∶10-100μm、BOPP∶10-100μm、PE∶15-150μm、NY∶10-120μm、 PET∶10-100μm、CPP∶10-100μm | |||

| Adjusting of register | Electric motor control (vertical and horizontal) | |||

| Constitution of Printing | Ceramic Anilox roller 6pcs、single doctor blade 6pcs、printing Cylinder for printing length 400mm、 PLC touch screen controller | |||

| Optional device :chamber doctor blade; | ||||

| Working Principle | synchronous belt driving | |||

| Printing precision | +/-0.15mm | |||

| Thickness of Plate (including the glue) | 1.7mm (please note us for different thickness) | |||

| Machine Voltage | 380V 50/60HZ 3PH | |||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Flexo Printing Machine Loading container,ship to other country.

Flexo printing machine,film blowing machine in customer fatory

Install Strech Film Machine in Mexico Customer Factory

Our Main parts cooperator as following brand(standard parts all made from China).

Drinking Straw Material Supplier

Global Service Network

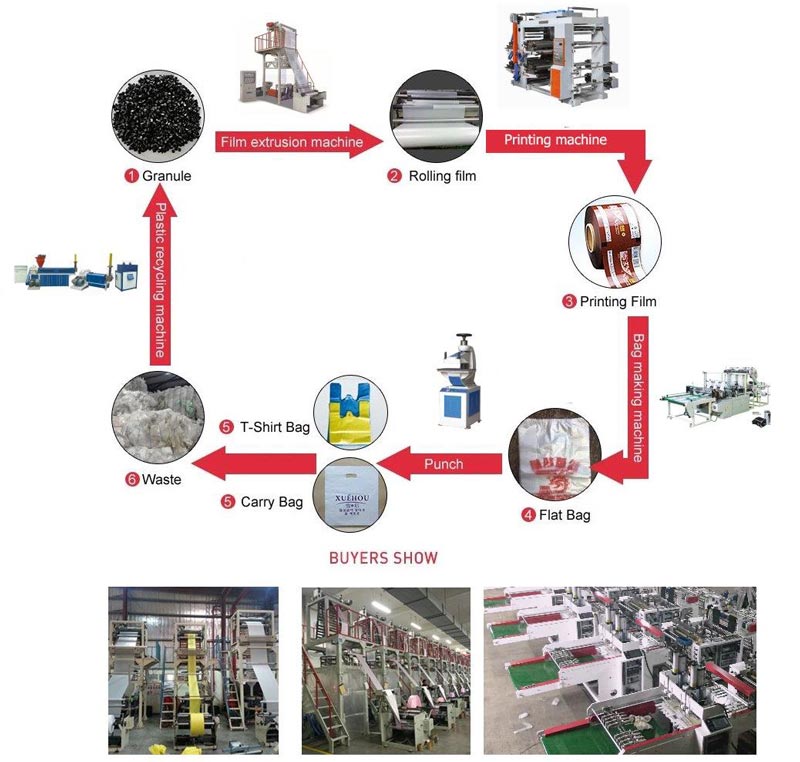

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;