PVC thermal shrinkable inflation film machine,also named PVC Shrink Film Blowing Machine,PVC Shrink Film Blowing Machine with extruder,winder,cooling system, Produce PVC shrink film,to pack paper tissue,Battery,bottle,wire,books.

PVC Shrink Blown Film Extrusion incorporates advanced technologies like rotary die head, frequency-controlled speed adjustment, and automated temperature regulation. The resulting products exhibit excellent plasticization and meet high-quality standards for film thickness consistency, clarity, flatness, shrinkage, and other crucial metrics akin to those in the printing industry. This compact and user-friendly PVC film blowing machine comprises essential components such as an extruder, rotary die head, cooling air ring, initial haul-off unit, hot water tank and sizing device, secondary haul-off unit (electrically operated), double-station coiler, extruder electrical control cabinet, and auxiliary machinery electrical control cabinet.

The PVC Shrink Blown Film Extrusion machine is designed for producing heat-shrinkable films of various specifications using PVC plastic resin through blown film extrusion. These films offer excellent transparency, glossiness, and high shrinkage properties. They have become a favored packaging material in various industries such as food, beverage, tea, glass products, handicrafts, sanitary ware, cosmetics, and electronics.

PVC hot shrink film

|

Item |

SJ-P200 |

SJ-P400 |

|

Screw and barrel |

40mm |

45mm |

|

Screw Ratio |

28:1 |

28:1 |

|

Capacity |

18-35kg/h |

35-45kg/h |

|

Film width |

30-200mm |

150-400mm |

|

Film thickness |

0.01-0.08mm |

0.01-0.08mm |

|

Lateral shrinkage |

40-60% |

40-60% |

|

Longitudinal shrinkage |

4-25% |

4-25% |

|

Motor |

7.5kw |

11kw |

|

Machine weigth |

1800kg |

2000kg |

|

Machine size(mm) |

9000*1600*1500 |

9000*1600*1500 |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

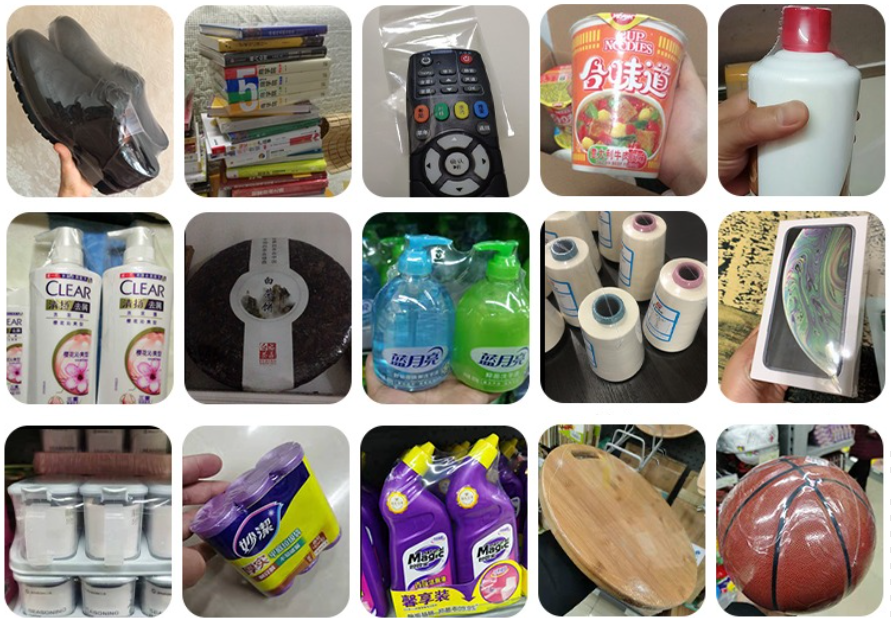

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;